Mich'Art is a small pottery studio and gallery located in Clarksfield, Ohio. The new building was completed in 2015, with the Grand Opening in February 2016.

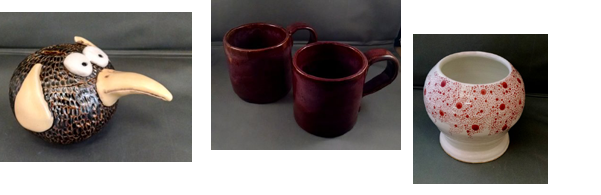

Mich'Art currently has two potter's wheels, two electric kilns, and one small kiln for testing glazes. All pottery in the studio is hand crafted on a throwing wheel, one piece at a time. Three different types of clay are used to create our pieces as well as a large variety of glazes.

Stoneware is a type of ceramic ware made from a heavy clay. Stoneware is made at extremely high temperatures, similar to other ceramics like porcelain. Both materials surfaced 2,000 years ago in China, inspiring new industry. China's knowledge of firing kilns for stoneware and porcelain clay gave them the bulk of the industry. When stoneware clay is fired to maturity, it becomes a piece of ware that is popular due to its sturdy build and chip resistant exterior.

Clays used for porcelain are generally of lower plasticity and "wet" very quickly. The most common uses of porcelain are for utilitarian wares and artistic objects. It can be difficult to distinguish between stoneware and porcelain because this depends upon how the terms are defined. A useful working definition of porcelain might include a broad range of ceramic wares, including some that could be classified as a stoneware.

Low fire ceramic clays are less dense than stoneware and are of high plasticity. They fall in betweeen the range of earthenware and stoneware. These clays are easily worked on the wheel and are very forgiving.

Each piece is thrown on the potter's wheel, to the artist's desired shape/form.

Piece then sits for 24 hours and dries to a leather dry stage. This is when the carving of the foot, handles, and any other carvings are made.

The piece then sits on a drying shelf for 2-3 weeks, this is known as green ware.

If underglaze is required, it is applied on the green ware.

The pieces are then loaded into the kiln and fired at cone 04 (1,940 Degrees F) for 6-8 hours. This is called Bisque Firing.

Kiln will stay closed after firing to allow the kiln and pottery to cool. Normally 12-16 hours.

Once cool, the kiln is then unloaded.

Glazes are then applied to each piece, some are dipped, but most pieces are hand glazed using a brush.

The pieces then go back into the kiln and are fired according to the clay and/or glazes used:

-Low Fire Cone 06/05 (1,830 to 1,914 Degrees F)

-Stoneware High Fire Cone 4/6 (2,167 to 2,232 Degrees F)

-Porcelain High Fire Cone 6/10 (2,232 to 2,381 Degrees F)

Firing times will vary from 6-12 hour, and cooling times from 12-15 hours.